- Features

- Product parameters

- Download

- leave a message

The production of the PMI rolled ballscrews has adopted a manufacturing process and equipment unlike other manufacturers. Combining advanced skills and the Bad Düben digital electric screw thread rolling machine, we adhere to a strict quality control policy at every stage of production, from the selection of ballscrew material and rolled processing to induction hardening heat treatment and post production. We are committed to providing clients with products of the best quality.

The combination of rolled ballscrews and ground nuts has replaced the traditional ACME screws and trapezoidal screws. This makes for a smoother operation while lowering friction and backlash. Moreover, the new technology has the advantage of faster production speed and lower prices.

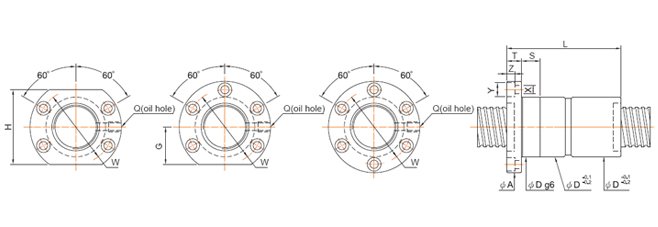

The advantage of internal ball circulation nut is that the outer diameter is smaller than that of external ball circulation nut. Hence it is suitable for the machine with limit space for Ballscrew installation.

It is strictly required that there is at least one end of screw shaft with complete threads. Also the rest area next to this complete thread must be with smaller diameter than the nominal diameter of the screw shaft.

Above are required for easy assembling the ballnut onto the screw shaft.

-

TEL:+86-531-85862926 / +86-18354189302

TEL:+86-531-85862926 / +86-18354189302 -

EMAIL:feimaiboss@feimaicnc.com.cn

EMAIL:feimaiboss@feimaicnc.com.cn -

FAX:+86-531- 88671786

FAX:+86-531- 88671786 -

ADDR:NO.50, Part 5, Times Headquarters Industrial park, Lanxiang Road, Tianqiao District , Jinan city

ADDR:NO.50, Part 5, Times Headquarters Industrial park, Lanxiang Road, Tianqiao District , Jinan city